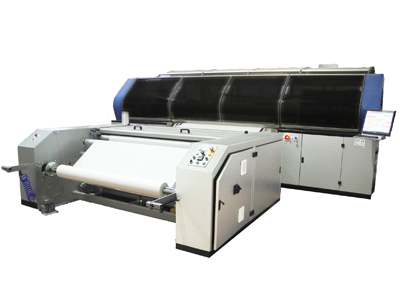

The Tiger-1800B MkII offers several enhancements to its predecessor

Mimaki has enhanced its production-class Tiger 1800B digital textile printer with new features and capabilities, in the form of the Tiger 1800B MkII, which was debuted at Fespa 2018 this week.

Offering several enhancements to its predecessor, the Tiger-1800B MkII prints at up to 385sqm/h and can support production ranging from sample-making to small-to-medium print runs. A new 1200dpi print mode is available for enhanced print quality.

A set of core technologies has also been added to the machine including the Mimaki Advanced Pass System (MAPS), which minimises banding and colour shifting by spreading the edge of each printing pass, making the boundary area a gradation, so resulting in a smoother printed image. Also incorporated is Mimaki’s Nozzle Checking Unit and Nozzle Recovery System, which enabling continuous high quality printing even if nozzle faults occur.

An extensive line-up of optional devices is also available to meet most fabric and transfer paper printing needs. This includes a feeding unit for roll media equipped with a centring device and tension bar; a jumbo roll unit to enable printing of long-length roll fabric or heat transfer paper; and drying and winding or pleating options for printed fabrics.

At Fespa the Tiger-1800B MkII was shown in combination with jumbo roll Mimaki Vision Jet-X sublimation transfer paper. Available in 1620 and 1830mm widths, the lightweight (57gsm) paper is suitable for producing almost everything from sports apparel, flags and banners requiring a high density of ink deposition, to fashion and home fabrics with lower ink coverage.

The company has also announced that the UCJV Series with LUS-200 inks will carry the 3M MCS Warranty, available from mid-summer 2018. The 3M MCS Warranty provides full protection for the intended life of each graphic, including fading, cracking, peeling and other aspects of the graphic performance.