Mimaki has announced the upcoming release of the UJF-7151plus II e, a next-generation flatbed UV printer designed for direct-to-object and industrial printing. The model is scheduled for commercial availability in November 2025, with its international debut set for the Printing United Expo 2025 in Orlando, Florida.

The new system is presented as an evolution of the company’s established UJF-7151plus II platform, offering improvements in precision, productivity, and cost efficiency. According to Mimaki, the printer addresses three key challenges in industrial digital printing: maintaining accuracy at high speeds, printing on curved or uneven surfaces, and producing three-dimensional textures.

“With the UJF-7151plus II e, we are taking another step forward in industrial-grade direct-to-object printing,” said Arjen Evertse, director of sales at Mimaki Europe. “This model offers advanced features that unlock new levels of versatility, efficiency, and cost control.”

The printer achieves image resolutions of up to 1800dpi, supported by enhanced position control and a reinforced structure for stable output. It includes light cyan and light magenta inks alongside CMYK, improving colour gradation and the reproduction of subtle tones such as skin or landscape shades. In practical operation mode, it can print 19 sheets per hour (710 x 510mm).

The model also introduces emboss printing up to 5mm for textured and raised effects, and a new Long Drop Mode that enables consistent results on substrates with height variations of up to 10mm, supporting applications on curved, moulded, or stepped parts.

Mimaki highlights the printer’s productivity and sustainability improvements, including a printable primer that enhances adhesion on materials such as glass, metal, and acrylic while reducing total print time. When printing layered jobs involving primer, white, and two-colour layers, the process is approximately 3.7 times faster than on previous models. An Ink Saving Function can reduce ink usage by up to 40% while maintaining colour fidelity and image quality, lowering operational costs and environmental impact.

To support workflow integration, Mimaki is introducing the Mimaki Application Assistant 2 (MA2), a new management platform that consolidates compatible software and keeps production systems up to date. It also works with RasterLink 7 RIP software, supporting variable data printing and workflow automation.

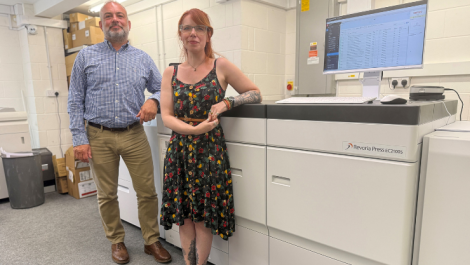

Designed for industrial applications, the printer’s table can support media up to 30 kilograms, allowing printing on heavier and more rigid substrates than comparable systems. “The latest model in Mimaki’s Industrial Products line-up delivers enhanced productivity, creative flexibility, and cost-saving innovation,” said Martin Southworth, reseller account manager at Hybrid Services, Mimaki’s exclusive distributor for the UK and Ireland.

The UJF-7151plus II e supports GreenGuard Gold-certified UV inks, including the ELH and ELS series, which are free from SVHC and CMR substances. It also features IoT functionality (MDL support) for integration with automated and smart manufacturing environments.

The printer will be available in the UK and Ireland from November 2025.