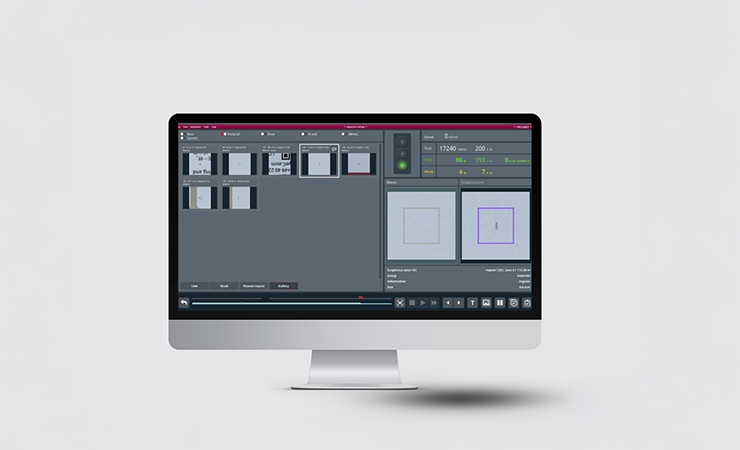

EyeC has introduced what it describes as the world’s first pre-trained AI for inline inspection. Now available across its ProofRunner Web product line, the new system moves beyond conventional defect detection by classifying deviations into defined categories. These include material, dust, spots, streaks, and “other”, with further classes to be added over time.

The AI can distinguish between critical issues, such as ink smears or material flaws, and minor deviations like dust or substrate inclusions. This means non-critical defects are recorded without triggering unnecessary production stops, reducing false positives, and maintaining production efficiency.

According to EyeC, the technology also supports sustainability goals. Its advanced image processing can handle the optical variations of recycled and other sustainable substrates, allowing it to separate acceptable irregularities from genuine defects. This aligns with regulatory initiatives including the EU’s Packaging and Packaging Waste Regulation.

The system has been trained on a dataset of hundreds of thousands of real print job images, enabling it to recognise and classify defects without the need for customer-specific training.

“While conventional systems only detect defects, our AI understands them like an experienced expert and distinguishes critical issues from irrelevant deviations,” said Nico Hagemann, director of product management at EyeC. “This empowers our customers to carry out precise inline inspections at full production speed while saving both time and resources.”

The AI-based classification will be included as standard in all new EyeC ProofRunner Web systems, with rollout to other platforms, including the ProofRunner Sheetfed, to follow in collaboration with OEM partners.