MMS Melter Mail Service, a German provider of data-driven print marketing services, has invested in upgrades to its existing fleet of 34 Kodak Prosper Imprinting Systems as part of a move to improve production performance and capacity.

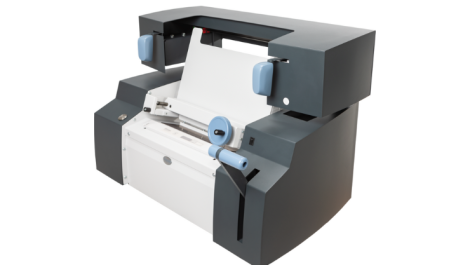

As part of the latest investment, Melter has upgraded its Prosper S10 systems and integrated them into two roll-fed Scheffer finishing lines. The setup allows the company to add variable and personalised content to offset pre-printed direct mail at speeds of up to 300m/min. Each line supports one- to four-colour imprinting with print widths of up to 980mm.

The investment also included the installation of two new Kodak CS450 System Controllers, which handle print data processing and system control.

Kodak’s Prosper S10 Imprinting Systems

According to the company, the upgrades are intended to increase productivity, reduce setup times, and support hybrid production workflows for large-volume direct mail campaigns. Kodak stated that the investment strengthens Melter’s ability to deliver high-speed and high-volume personalized print services to its customers.

“By reinvesting in Kodak, we have modernised our inkjet imprinting technology and made it future proof,” commented Daniel Melter, member of the executive board of MMS Melter. “Concentrating our Prosper printheads on high-performance roll-fed finishing lines has resulted in increased productivity and faster setup times. Overall, we have created more powerful facilities for high-performance, hybrid production of sophisticated direct mail.”

Denisse Goldbarg, head of EAMER sales and chief marketing officer at Kodak, said: “Following this latest investment, Melter can offer its discerning customers even faster and more reliable high-volume direct mail manufacturing.”

Founded in 1912, the family-owned company employs around 200 people and is headquartered in Mühlacker. Melter operates Prosper Imprinting Systems equipped with Kodak Proseper S10 printheads, making it one of the largest users of the technology in Europe.