Customers of Friedheim International will have a lot to look forward to when the company visit drupa next week. An impressive array of innovations and solutions will be presented by the company’s partners.

Friedheim International’s partners will showcase their latest innovations. Here are some of the ones to look out for.

Hunkeler – Hall 8a / Stand C20

An extensive array of digital solutions will greet visitors not only to Hunkeler’s stand, but also on over 14 other company stands around the DRUPA halls. Items and processes on display include:

– High-performance variable format book production

– Dynamic Book De-stacker

– Newspaper and booklet production with automatic changeover

– ‘Booklet’ application with safety features

– Premium quality direct mail production

– Web Inspection, Control & Tracking, and Site Manager

– Imposition workflow automation in partnership with Ultimate

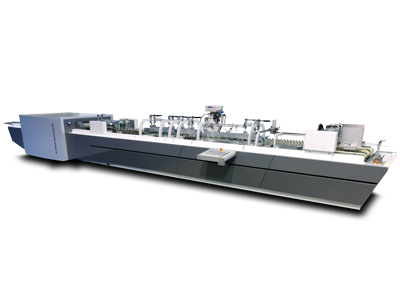

KAMA – Hall 2 / Stand A15

Among the highly innovative machine solutions for trend-setting short runs and digital packaging printing that KAMA is demonstrating are the following:

– DC 76 ASB – an automatic die-cutter

– NEW FF 52i – the first folder-gluer specifically for short runs.

With the extremely short set-up times, faster finishing, in-line stripping without tools and automated set-up, the solution paves the way for making short run converting of folding boxes both efficient and profitable.

A further highlight of the stand includes a servo-controlled hot foil stamping unit, which is capable of producing up to 50% more performance and greater flexibility for the professional finisher.

Komfi – Hall 6 / Stand E03

Komfi will be demonstrating a new dimension in print for their visitors, with multiple new launches of modules and machines along with improvements to the Spotmatic 54.

New imiJET BE70 book edge printing machine

– Semi-automatic inkjet book edge printer (hand fed)

– UV cured ink, 4-colour and above

– Very easy to use intuitive set-up and operation – very short make ready time

New Amiga 76 + OTF module

-Built-in foiling module and stand-alone flying knife module for PSA (pressure sensitive) film processing and label market

New Sirius 107 + linear hot knife and modification for corrugated stock lamination

New Delta 52 + Sagitta 52 and 76 (window patching)

– Alternative to window patching with the windows already cut and a layer of cellophane applied by the laminator

Fullmatic 52 (Spot UV coating)

Amiga 52 (embossing)

Spotmatic 54 (UV varnishing)

Palamides – Hall 6 / Stand E05

Palamides will be highlighting a number of different equipment processes during DRUPA 2016. These include:

– New Lay-flat perfect binder especially for digital printing. ‘Smartflat’ technology allows with the new ‘Smartliner240’ perfect binder to produce books in an environmentally friendly and energy efficient way. The Smartliner240 is a single-clamp perfect binder with an effective output of up to 240 books per hour. Automatic set-up allows easy handling for operators.

– Delivery system: Automatic Tray Filler. In a live demonstration Palamides will put mail pieces, coming out of a Kern 3600, directly into post boxes. The extremely quick change of post boxes makes the tray filler essential in automated mail delivery in places such as output centres, letter shops and print shops.

Lasercomb – Hall 10 / Stand B44

Sharing a stand together with Serviform and Boxplan, Lasercomb will be demonstrating two machines:

– The ProDigi 0813 With a NEW controller which includes the possibility of working with the Eurosystems ‘OptiScout’ software for the complete workflow.

– New oscillating cutting generation for cutting rubber and various materials.

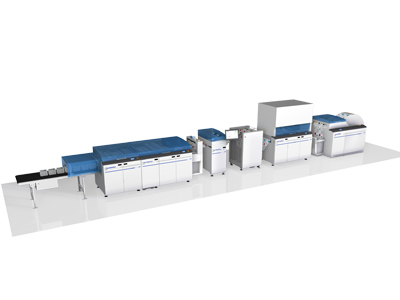

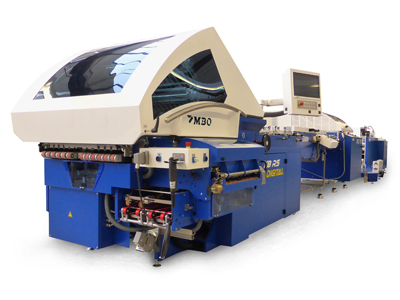

MBO – Hall 6 / Stands B40-1 / B40-2

Under its NEW ‘Finish First’ slogan the MBO Group will be demonstrating advanced finishing technology and solutions that are designed to help users to improve their efficiency and productivity.

There will be a total of 11 MBO and Herzog + Heyman finishing systems on display covering offset print applications, digital print applications, as well as specialty applications such as direct mail, pharmaceutical finishing and packaging.

New Monza folding system featuring the New A10 log stacker delivery. Designed to greatly reduce the labour involved at the delivery, enabling operators to run the machine at higher speeds without additional personnel.

The Le Mans high-speed folding system will mark a milestone in how to industrialise finishing concerning speed and ergonomics for extremely high outputs.

Live job changeover demonstrations of a MBO K8 Automatic will show visitors ‘first-hand’ how automation can greatly improve make-ready times.