EMT International has introduced a new heavy-duty dynamic perforating solution aimed at supporting the growing use of thicker substrates in high-speed digital print production. The company says the new system extends its existing dynamic perforating technology to handle materials up to 18-point, addressing a finishing bottleneck as inkjet applications continue to move beyond lightweight papers.

Based in Hobart, Wisconsin, EMT is known for supplying finishing technologies to the print and label markets, particularly for continuous-feed and inkjet environments. The latest release responds to increasing demand from printers producing transactional documents, direct mail, lottery products and fanfold applications, where heavier stocks are becoming more common but can be difficult to perforate cleanly at speed.

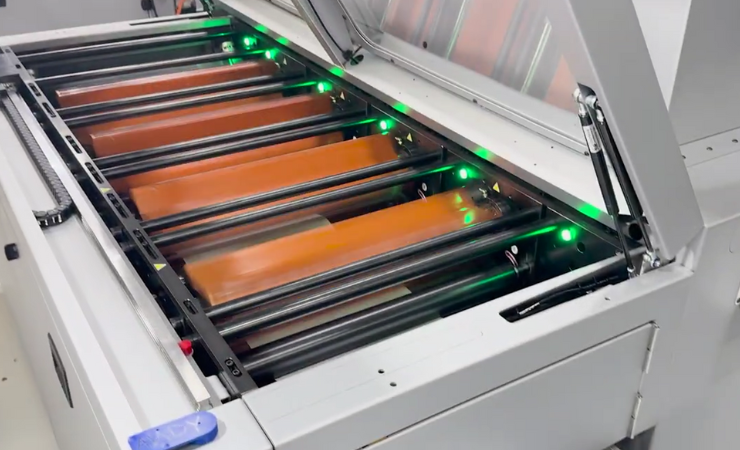

According to EMT, the new solution has been engineered to maintain perforation quality, registration accuracy and productivity when processing thicker substrates. It builds on the company’s established dynamic perforating approach, which uses software-driven control rather than fixed mechanical tooling, allowing perforation patterns to be adjusted on the fly.

“Digital print continues to push into thicker substrates, and finishing has to keep up,” said Jordan Geurts, vice president of technology and solutions at EMT International. “This new heavy-duty dynamic perforator was engineered specifically to handle that shift, combining EMT’s software, motion control, web handling, and mechanical precision into a solution that delivers clean, repeatable results on heavier stocks.”

The system is designed for both inline and nearline use, making it suitable for integration with modern inkjet presses as well as retrofitting into existing finishing lines. EMT says this flexibility allows print service providers to adapt to changing job requirements without extensive reconfiguration or downtime.

Key features highlighted by the company include the ability to perforate substrates up to 18-point, consistent results at production speeds of up to 1,000 feet per minute, and software-controlled perforation patterns that remove the need for multiple physical perf cassettes. The mechanical design has also been reinforced to cope with the stresses associated with heavier materials.

EMT positions the new perforating solution as particularly relevant for applications such as lottery tickets, transactional documents and specialty digital print products, where durability and clean tear-off performance are critical. With the launch, the company aims to give printers greater freedom in substrate selection without having to compromise finishing quality or throughput.