Plockmatic Group has announced the commercial availability of its latest digital finishing system, the ColorCut SC7800 Pro-RS XL, a compact B2 sheet cutter and creaser designed for print and packaging environments.

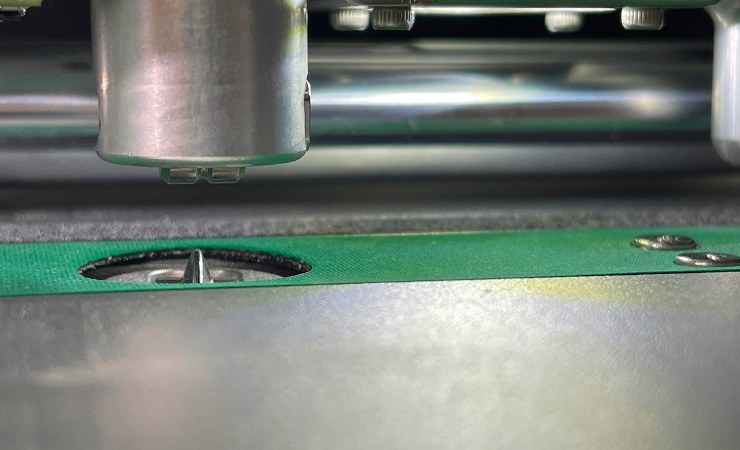

The SC7800 Pro-RS XL is the newest model in the company’s ColorCut SC7000 series. It features a triple-tool cutting and creasing system that includes a patent-pending tangential creasing tool with both convex and concave elements. According to the company, this design allows double-sided creasing, with tools operating above and below the sheet simultaneously to create formed creases similar to those produced by traditional platen machines.

The system supports media sizes up to 520 x 740mm and can process materials up to 450 microns thick, including synthetic substrates. It also offers perforation capabilities for applications such as folders, packaging, and point-of-sale materials.

Automation is enabled through a QR code-based workflow, allowing up to 1000 sheets to be processed in a single unattended run, even when multiple jobs are stacked together. Job accuracy is supported by SmartMark registration using the included ColorCut Pro software.

Mark Baker-Homes, vice president of Plockmatic Group’s packaging and label business unit, said the company has seen strong early interest in the new model. He highlighted the system’s use of a floating second creasing wheel beneath the media, designed to move in synchronisation with the upper tool carriage to replicate a traditional male and female creasing effect.

He added that the system combines elements of flatbed, sheet-fed, tangential, contour-cutting, and die-based technologies, enabling digital cutting and creasing directly from printed artwork without the need for physical dies. The machine was developed in Sweden and is positioned as a low power consumption option for environmentally focused operations.