Full Spectrum has strengthened its position in the wide format and packaging markets with a dual equipment investment from International Graphic Supplies (IGS), installing a Titanium Digital CAD Cutting Table alongside a Platinum 1325 UV printer.

The Basildon-based printer, whose client base spans luxury travel, hospitality, fashion, lifestyle brands, publishing and retail, said the combined investment underpins its strategic growth plans through 2026 by enabling end-to-end production of complex wide format and packaging applications.

The decision followed a long-standing relationship with Managed Technology, which introduced Full Spectrum to the IGS portfolio and facilitated a site visit to an existing customer running the equipment in production.

Kevin Walker, CEO at Full Spectrum, said the ability to see both machines operating together was key to the decision. He commented: “One of our goals for 2026 is to continue to expand our portfolio of packaging and wide format services. It was therefore vital that we acquired highly precise and complementary machinery. The demonstration of the Platinum UV printer and the Titanium cutter working together at a live site was crucial. Through consultation, we focused on the Platinum 1325 and the Titanium 2516 Conveyor model with router to achieve our vision.”

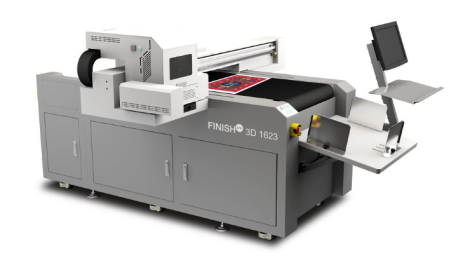

The Platinum 1325 UV printer is designed for direct-to-substrate printing across a wide range of materials commonly used in wide format and packaging applications, feeding directly into the finishing stage. Finishing is handled by the Titanium 2516 Conveyor cutting system, which features a 2.5m x 1.6m cutting bed and conveyor belt for continuous operation.

Peter Flynn, managing director at IGS, said the specification was tailored to Full Spectrum’s requirements. “Full Spectrum has the highest reputation for print precision and quality. Having listened to their dual requirement for both printing and finishing high-end, bespoke applications, we felt the Platinum 1325 and the Titanium 2516 were the perfect combination.”

The Titanium system is equipped with multiple tools, including routing for rigid substrates, drag knives, and creasing wheels for packaging work, oscillating knives for heavier boards, and kiss-cutting for labels and stickers.

The combined system is already being used to support short-run packaging prototypes, cut-and-crease work, and a broader range of wide format products including wall, floor, and window graphics, complementing Full Spectrum’s existing small format digital capabilities.