Digital printing is claiming a growing share of the textile market, with over 5% of all textiles in the world now being printed digitally, but it’s worth noting that there is a lot more to it than just printing designs on fabrics.

Consumer satisfaction and sustainability concerns are both of huge importance in the garment sector and both are impacted by a process called softening. Sharon Donovich, product marketing manager at Kornit Digital explains why softening is so important, its impact on the environment and why his company’s solution is ahead of the competition.

Fashion-conscious consumers have changed their purchasing behaviour. The ‘look’ itself is no longer the only important factor, the comfort that fashion should offer now also has priority. The softness of the textile is an important parameter for comfortable clothing. In fact, softness is a basic prerequisite for comfortable clothing. The wearer must feel that softness in order to trigger the decision to purchase the garment.

Additionally, criticisms against ‘fast fashion’ have been gaining ground for some time. Environmentally savvy shoppers are increasingly conscious of the implications of fast fashion on landfills, labour and general waste, with some brands routinely burning unused stock. But from fast fashion to high-end luxury apparel, and everything in between, a lesser-known process continues to do lasting damage: the environmental impact of textile finishing – including softening of the fabric – which also affects our health.

What is textile softening?

Textile finishing is the process of treating a textile to give it a number of qualities, such as moisture wicking, softness, stain resistance and durability. It is one of the most polluting sides of one of the most polluting industries, with 25% of global chemical output stemming from textiles alone – and the chemicals used are often far from safe. The softness of your yoga clothes can be credited to siloxanes: synthetic compounds that build up in the environment and harm aquatic life. Your shirt is wrinkle-free thanks to formaldehyde, a known carcinogen that can trigger allergic reactions and contact dermatitis in people with sensitive skin. And your coat or jacket? Its water-repellent qualities come courtesy of perfluorinated chemicals, which can bioaccumulate in the body and cause diseases and increased mortality in animals.

To create a permanent change here, fashion brands need cleaner options.

Consumers are coming to value softness as a much as they do design or provenance

Why is softening a crucial process in textile production?

Softeners have gained great importance in textile finishing; almost no piece of textile now leaves a production facility without being treated with a softener. This treatment gives the textiles the desired hand feel, simplifies further processing and improves the handling properties. A nice, soft hand feel is often a key criterion for buying a textile, and is therefore of vital importance for marketing many textiles.

How is softness achieved today?

To obtain the desired softness in a cotton textile, several factors must be engineered in the product from the beginning. The first consideration is the structural composition of the fabric. Another consideration is how the fabric is mechanically handled during the preparation, dyeing and finishing processes. Chemicals used in preparation, dyeing and finishing will likewise affect the aesthetics. Often garments are post-treated not only to control shrinkage of the final product, but also to soften the hand feel. Many decisions need to be made to create the desired product. Some of these considerations are based on the product desired, specifications required, cost and the equipment available at the finishing plant.

To change the hand properties of a fabric, mechanical, physical, chemical or combined techniques can be applied; that means there are multiple steps involved in the process, including machinery, labour and time.

As a general rule, the softening agents applied are hygroscopic or lubricating agents, which facilitate the fibres sliding within the fabric structure, thus granting easier deformation and creasing of the fabric. In most cases, the duration of the effect is limited since the products applied during the treatment are eliminated by subsequent washing; for this reason, they must be applied in the final stage of the treatment.

Kornit’s solution

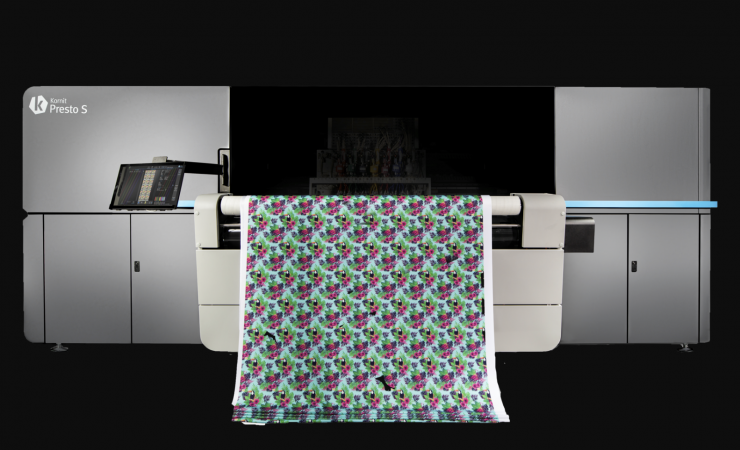

So what’s the solution to this conundrum? The Kornit NeoPigment Robusto dry digital Softener, integrated with the Presto single-step print process, eliminates barriers between waterless, digital pigment decoration and the growing challenges of fashion on demand, opening a world of business opportunities with vibrant colours, intricate design capabilities, and a fabric touch that we think is second to none.

Kornit’s Softener solution is applied during the printing process. No additional time, labour or equipment is needed, and most importantly, it is a sustainable solution carrying Eco Passport certification and GOTS verification.

.

So basically, Kornit printing is not a printing only machine but a complete line which comprises pre-treatment and also post printing treatment. However there is no escape from the chemistry. No step is eliminated.

One of the reason that Kornit is very expensive is that each machine has to have pre-treatment and post-treatment arrangment. This is a bit redundant if you can have one centralised pre-treatment equipment feeding multiple printers and likewise, one post-treatment line being fed by multiple printers. The fabric softening can be achieved this way too.