One of the lesser miracles of digital printing is how easy it is to get into small scale and bespoke garment printing. Simon Eccles looks into what could be a lucrative sideline while commercial print recovers

Digital presses are usually reasonably (and sometimes very) substantial investments, but around £3000 is enough to get you started with an entry-level CMYK single-garment pigment printer or dye sublimation heat transfer system, while £10,000 to £20,000 gets you a really good and productive setup. For an existing printing company that’s used to handling image files and organising workloads, it can be a useful bolt-on business to offer to existing clients or online to B2C customers. If it doesn’t take off you won’t have lost much, but if it does, the profits can be reinvested in more sophisticated printers for greater productivity and extended functions.

There seems to be an almost limitless demand for printed garments, with the most immediately obvious being the timeless cotton T-shirt or the related sweatshirts and hoodies, plus baby wear, caps, branded workwear and in some cases denim trousers and jackets. This year’s must-have printed garment is a brightly patterned printed face mask, for obvious reasons.

‘A lot of the enquiries we are receiving steer towards smaller items like baby grows and kids’ clothing, T-shirts and tote bags,’ says Lauren Swinnerton, marketing manager of Roland DG UK.

Nick Macfarlane, direct-to-garment (DtG) sales specialist at Ricoh UK, says that DtG is an entry into a big market, quoting research that the worldwide promotional and personalised goods sector was worth around £50 billion as retail revenue in 2017. ‘Wearable items, like T-shirts and sweatshirts, make up a big share of the promotional and personalised goods market, [at] 31%. Bags comprise a further 8% and textiles 3%, meaning businesses could access almost half of the available work with the right textile printing systems,’ he says. He admits that a lot of this is mass-produced by analogue print, but about 9% is digital, still representing a huge market.’

All of the DtG printers on the market are inkjets using water-based pigment inks that are then bonded to the fabric by heating for a few minutes. Unlike the rival dye sublimation process, pigment inks work with natural fibres, including cotton. The ink does not form a complete chemical bond with the fibres in the same way that dye sublimation does with polyesters, so the images will eventually start to wear off after many runs through the washing machine.

If you choose a DtG printer that includes white ink, then you can use this as a base layer on black and darkcoloured garments. ‘Pre-treatment will be required for dark garments, but not for white/light garments where white ink isn’t being printed,’ points out Grant Cooke, product manager at specialist dye sublimation and DtG supplier Xpres. Pre-treatment can be a spray, or you could buy a dedicated machine that just applies the liquid where it’s needed on the garment. Amaya offers three pre-treatment units with prices starting at £2755.

There are also reactive dye or acid dye inks that will bond permanently to natural fibres, but these need special preand post-wash processes and are not supported on small DtG printers.

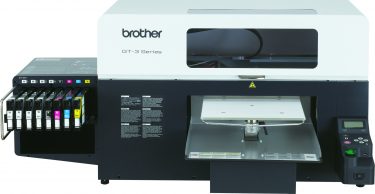

Brother has been making textile printers for some 20 years

Pigment parade

In our ‘entry-level definition’, which we’ll somewhat arbitrarily define as ‘below £20,000,’ there’s a pretty wide choice. In alphabetic order the main established manufacturers are Brother, Epson, Polyprint and Ricoh, with Roland DG as an OEM of Ricoh at this level.

There’s no easy way to compare these on productivity, as speeds aren’t generally given and in any case depend on the size of image being printed. Buying extra platens means you can set one up while another is printing. On the whole, paying more tends to get you a faster, more robust printer with white ink, but the best thing to do is try a few out in dealer showrooms before deciding.

Brother has been making textile printers for about 20 years. Its entry-level DtG model is the GT361 for platen print areas up to 335 x 405mm, with a list price just under £12,000, though reseller MHM Direct GB was offering a third off at the time of writing. This offers CMYK plus two white print heads, printing at up to 1200dpi. Extra platens of various shapes and sizes, including one for trainer shoe sides, cost about £300 each.

The top Brother GTX Pro model offers a larger and more robust twin-head print engine for £19,995, including Graphics Lab software, with an automatic platen height adjustment, a new white printhead with ink recirculation and automated self-maintenance routines. Its maximum platen size is 406 x 533mm. There’s also the GTX Pro Bulk variant, which includes a bulk ink feeding system for £28,495 (plus £4295 for a starter kit of ink).

Epson currently offers two DtG printers, the entry-level F2100, available with CMYK for about £11,000 or CMYK + white for about £13,000, both with design software, and this year’s launch of the faster, more advanced but much pricier SureColor SC-F3000 (‘under £40,000’) with auto platen height adjustment and facility for bulk ink feeders. Polyprint, a Greek manufacturer with a long history in conventional printed textiles, has been selling DtG printers for longer than most of the others, according to Charlotte Darling, sales director of UK distributor Amaya Sales.

Amaya currently offers two recently updated Polyprint TexJet DtG models. ‘These will get you on the stepping stones to garment printing,’ says Ms Darling. The smaller model is the TexJet Shortee2, offering a maximum platen format of 320 x 450mm. It costs from £7950 with a standard set of platens of different sizes and shapes; others can be bought. The larger machine is the TexJet Echo 2, with a maximum format of 410 x 600mm, costing from £10,450. The smaller platens are interchangeable between the two printers.

Ricoh is a comparatively recent entrant into the market with its A4 format Ri 100 and Ri 1000 entry-level printers (there are also high end Ri 2000 and Ri 3000 models) and it’s done well with some strategic marketing deals with resellers such as Resolute DtG and TheMagicTouch. Roland DG also rebadges the Ri 100 as the BT-12.

The Ri 100 is very compact and attractively priced at just under £3000, including layout software and a heat fixing unit that can be stacked underneath or alongside the printer. It’s CMYK-only so has to be used with white or light coloured garments. ‘It’s an entry-level device that lets you easily see if you have enough work to buy our next machine up, the Ri 1000,’ says Ricoh UK’s Mr Macfarlane.

Costing about £20,000 all-in, the Ri 1000 offers CMYK plus 2x white inks and the more advanced AnaRip software as standard. Ricoh is about to launch new software with improved colour management.

Roland DG’s entry level DtG printer is the CMYK VersaStudio BT-12 at £2499 with a heat finishing unit, as mentioned above, a rebadge of the Ricoh Ri-100. The company does build an interesting pigment printer of its own, the £56,999 flatbed Texart XT-640S-DtG, which can take multiple garments stretched onto four, eight or 12 frames across the bed.

‘Smaller businesses or new businesses make up a large percentage of BT-12 users,’ says Ms Swinnerton. ‘As this machine appeals strongly to a start-up business, we’ve seen that it is a first machine for people as a stepping stone into garment printing. Some may have tried using a cutting plotter, but in general this is their first ‘big’ purchase.

We see a lot of the Etsy/Not On The High Street type of customer, but there’s also been a notable uptake with on-demand promotional gift production.’

Brother has been making textile printers for some 20 years

Dye-sub alternatives

The dye sublimation process is widely used but only works on textiles with a high polyester content. This is great for sportswear and some workwear (including hi-vis garments), but not for garments with high proportions of natural fibres such as cotton.

There are no direct-to-garment dye sublimation printers yet. Some roll-fed dye-sub printers will print directly onto bolts of cloth (going through heat fixing calender rollers afterwards), but for made-up garment work the only dye-sub option is to print onto paper transfers (normally with a roll-fed inkjet) and then use a heat press to complete the sublimation process onto the garment. Some heat presses have interchangeable shaped platens to take items such as sleeves or baseball caps.

A dye sublimation printer can be more versatile than a dedicated DtG printer, as you’ve also got the option of using dye-sub and the paper transfer with other substrates, such as phone and tablet cases, mugs, caps and so on. All sorts of polyester ‘blanks’ as well as printers and inks, are available through specialist resellers such as Novachrome, Dye Sublimation Supplies, Merlin Transfers and Xpres.

On the other hand, transfers are more fiddly to apply and heat-fix than using a dedicated DtG printer. ‘It is a bit of a dilemma,’ admits Phil McMullin, sales manager for pro graphics at Epson UK, which sells both DtG and dye-sub printers. ‘But dye-sub is the most flexible and the new range of artificial fabrics is outstanding. So whilst our DtG unit is a great option, you might want to start with our new SureColor SC-F500 entry level dye-sub. A 24in printer for less than £2000!’

With prices like this, there’s no real need for an either-or decison between entry-level DtG and dye-sub transfer. You could buy both together with a decent heat press and still get change out of £10,000.

You may not even need to choose between them.

Dye Sublimation Supplies is UK agent for the US Vivid Chemicals’ Reveal sublimation inks, which are claimed to work with both natural cotton fabrics as well as polyester materials and blanks. Vivid hasn’t revealed how this actually works and there seem to be few hands-on user reviews, but it involves using transfer films and three clear ink cartridges in a dongle-protected Epson SC-P600 inkjet. A system to put white plus colour onto dark fabrics has been promised for some time. A starter package with printer, heat press, transfer film and inks costs £2276.85.

Dry toner togs

Another alternative is dry toner heat transfers, which offer the same sort of versatility as dye-sub but work on a much wider range of textile types, both natural and synthetic, and flat solid surfaces with no polyester required. On the other hand, just like inkjet pigment, the bond to textiles isn’t as strong as dye-sub, which affects washability.

These transfer types typically use the OKI range of affordable A4 and A3 desktop LED dry toner printers. Some of these printers offer white ink as a fifth colour, so they are suited to dark fabrics with the right transfer paper. TheMagicTouch in Dunstable has been a big exponent of these over the years, having developed its own wide range of transfers papers that run in the OKI toner printers that it also resells. A big breakthrough came a few years ago with its WoW! Papers that offer a two-stage white base layer system to allow bright colours to show on black and dark fabrics. Its more recent T.One is a one-stage transfer but its white isn’t so opaque.

Amaya sells a rival toner transfer system called Forever, also for use with Oki printers, with a wide choice of paper types and applications, including the two-stage Laser Dark for dark fabrics.

Roland DG’s entry level DtG printer is the CMYK VersaStudio BT-12

Hot fashion

All these garment methods need post-print heat treatment, which can be a simple heated cabinet for DtG pigment inks, a conveyor tunnel to automate the process, or a heat press for dye-sub and dry toner transfer work, ideally with interchangeable shaped platens. Tunnels are actually quite expensive – typically £6000 to £15,000. Screen printers may have one already.

Heat presses start at around £350 for a basic hand-pulled type, £1200 with a decent timer and auto release, or £2000 and above for pneumatic operation with automatic pressure and thickness adjustment. Twin-table pneumatic models let you set up one garment while another is being pressed.

The beauty of a heat press is that the same one could be used for more than one process – DtG printing as well as dye-sub, toner transfer or even the older but still popular cut vinyl transfers. TheMagicTouch also sells sheets of Premium Flock HTV in 16 colours. This simulates raised embroidery and is also applied by heat press. That needs a low-cost contour cutter – a Graphitec Silhouette hobbyist cutter costs just £290 – to create the shapes.

With low entry costs by commercial print standards, there’s little to lose by having a go and if it doesn’t work out, you can print T-shirts for friends and family this Christmas. And if it does hit a market niche, there are bigger, faster and more versatile machines to upgrade to.