These days every business needs an online presence but web-to-print systems can go beyond being a simple sales tool to become a valuable part of the production process. Nessan Cleary explains.

A print business is defined by the things that it can print but really it’s the ability to sell that print that determines the success of the enterprise. Nowadays every business, in every industry, needs an online presence, if only to advertise what it can do and offer a point of contact for customers. Naturally, many companies also use their websites as a direct sales tool where customers can order goods and pay for them then and there.

For a print company this could be as simple as listing the types of products that can be printed and asking people to submit their artwork. But a true web-to-print (W2P) system should go beyond this. Aaron Tavakoli, product marketing manager for EFI Storefront, explains, ‘We typically define W2P as a purpose-built e-commerce platform that enables you to specify the print materials as well as other items. So conventionally e-commerce will let you order products but the key difference is that a web-to-print system enables you to specify the item for production.’ In other words, W2P isn’t just about selling print but about pushing those orders into the production system, and as such should be viewed as part of the overall production workflow.

Mr Tavakoli points out that just about any system can handle static print items like pre-printed shells and non-printed items. But there is a range of other features that users should consider. This includes the ability to handle ad hoc work, where customers supply their artwork at the point when they place their orders with no prior arrangements. Another feature is the ability to handle kits or bundled orders, where customers might order a number of different products but want it all handled and fulfilled as a single order.

Most W2P systems will also support a variable data printing (VDP) marketing model, where you pull information from a database to build a mailshot with multiple versions or individual personalisation and send that to many thousands of people. Some W2P software also allows customers to design their own documents, with design elements and pagination adapting to fit the content. EFI, for example, has a Smart Canvas feature that lets customers build documents online from scratch, starting from a template. Print service providers can build a lot of flexibility into these templates in order to allow users of the system to design documents without compromising their corporate branding.

Scodix has developed its own web to print solution, Studio W2P, which integrates with other W2P and is designed to persuade printers to offer the Scodix enhancements to online customers.

Integration with production

If W2P is truly part of the production system then it obviously has to be integrated with the rest of that workflow. Mr Tavakoli says that to this end there has been a lot of convergence between MIS and W2P applications over the last five years.

He advises that it’s important to have a strategy to ensure the two systems are integrated, but adds that ‘integration’ is a term that’s bandied around a lot and that often people just mean a relatively simple XML-based API (application programming interface). He says, ‘But we mean a common shared database to exchange order profile data, job production templates and the fundamental details of an order. You don’t want to have to configure user profile data or the pricing for a job in two different locations. A fully integrated system should allow you to do that once and to share that information across both platforms.’

To this end EFI has integrated its W2P system, now called MarketDirect Storefront, with its various MIS offerings via its Productivity Suites. Each of the Productivity Suites is based around one of the MIS programs, with different options for enterprise-level organisations or small bureaux, or for wide format printers or packaging converters. All the various modules within these suites are developed side by side and released at the same time so they are all updated simultaneously. Mr Tavakoli says that EFI works from a number of certified workflows that describe how data is exchanged between the MIS and W2P, explaining, ‘We test against these certified products to ensure the workflow is maintained.’

Mr Tavakoli says that EFI does have plenty of customers using its MarketDirect Storefront with other vendors’ MIS solutions, and that there is a good level of integration through XML and JDF interfaces, but that there is a deeper level of data exchange when its used with an all-EFI system.

Aleyant has developed the Pressero W2P software, which is available as an entry-level Advanced version, or the more capable Premier version. Both run in the cloud though there is an option for a dedicated cloud server with the Premier DS edition. They offer public retail customer websites with the option for further private business-to-business sites and a template system for building ‘eDocs’ for creating variable data documents. The system includes content management so that any print shop should be able to put together a decent website with plenty of information and even a blog about itself. The Premier version can host more sites and offers an automated workflow integrator that automates processes such as sending or renaming files so that they match whatever the workflow is expecting. Both versions can be integrated with MIS, imposition and workflows. Pressero creates press-ready PDF files that can be sent straight to a print queue.

Aleyant also runs a team dedicated to helping printers build their own workflows, Pressero Integrated Services. One of the recent fruits of this has been to develop integration with EFI’s PrintSmith Vision and Pace MIS. This was originally done for a US customer, Alliance Franchise Brands, but is now available to anyone using Pressero.

Trent Foreman, Aleyant’s director of product management, explains, ‘As long as users have the Pace or PrintSmith Vision API available, they simply need to turn on the integration within Pressero, set up appropriate login conditions, and map fields so information can pass back and forth. It’s easy to do, and it can start pushing information within a few hours, with full deployment in a couple of days.’

This means that when Pressero picks up an order, or change to an order, then the job, with all its associated elements including production files, contacts and shipment entries are automatically generated into the EFI MIS system. This makes for a faster system and eliminates the risk of errors being generated by manually re-entering that information.

Aleyant has also integrated its Pressero W2P with Fujifilm’s XMF Workflow – Fujifilm also sells Pressero to its customers. This enables automated transmission of job data from a web storefront directly into the XMF workflow, enabling automated production and job submission, including the selection of an appropriate imposition template, for improved operational efficiency, reduced errors and faster time to market.

Fujifilm sells Tilia Labs’ Phoenix automated imposition system, which is also integrated with Pressero. This in turn means that Pressero can take in jobs, send print ready PDF files via a hot folder to Phoenix, which can then automatically impose that job.

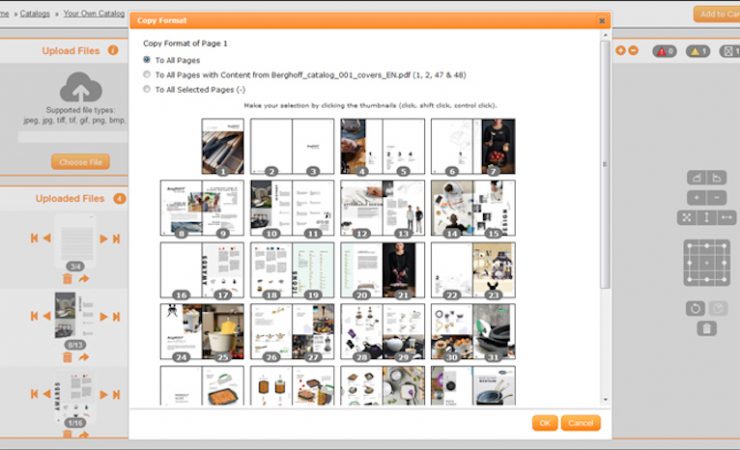

Agfa has taken a slightly different approach in developing its StoreFront W2P software with dedicated versions for both its Apogee prepress and Asanti wide-format workflows. The latest version includes JDF Production Intent information that indicates if a job is intended to be produced using an offset, digital or inkjet press. It can handle a range of items such as posters and banners as well as catalogues, magazines and brochures. It shows the number of pages in these products with preflight errors or warnings as well as how many pages are still missing. When the ‘Add to cart’ button is clicked, StoreFront will still do a full preflight before adding the bound product to the cart.

Vpress sells Coreprint, designed as a relatively inexpensive way of giving printers an online storefront of products on offer. There’s a template system to help printers create those products and customers can review and submit their artwork, with print-ready files sent directly into the workflow.

There’s also a more advanced version, Coreprint Pro, which is more of a brand management and print procurement system that can be used to run portals for multiple clients, complete with variable product templates. It has a number of modules, including CoreDAM for digital asset management, CoreDirect for variable data printing, and Elements for instant pricing even without an MIS. It comes with an API that allows it to be integrated into most common MIS and CRM programs.

Built on blogging

Vpress recently added a WooCommerce plugin, which extends Coreprint to the WordPress platform. WordPress is a fairly common content management system that’s popular with bloggers but is also suitable for business thanks to its own WooCommerce plug-in. The Coreprint version of WooCommerce integrates directly with Coreprint, allowing anyone to set up a WordPress site and then add the W2P functionality.

Kelvin Bell, sales director at Vpress says, ‘What we have done here is release a highly personalised, quick to deploy and cost-effective solution to a market where there really is nothing to compare; usually these types of solutions were £10,000 upwards, whereas now they are a fraction of the cost. Any print provider or customer can implement a solution to personalise anything into any production workflow, it really is unique.’

Flex4 too has used WordPress as the basis for its Online Print Solution W2P. This has allowed it to leverage the flexibility in layout design and ease of use associated with WordPress, including the ability to run off a mobile or tablet device as well as a computer screen. There are four different levels, with some allowing users to set up private storefronts, create templates and generate print-ready PDFs, and with the top of the line OPS-4 also able to import InDesign’s IDML format.

Template-based W2P is also offered by the eponymous RedTie Template software which the company says offers an extensive set of product and webstore customisation tools for flexibility, backed by walk-through guides on its own website, plus advice on configuring the software and supporting the implementation into the printer’s business.

Whether it’s a cost-effective storefront for configuring and selling standardised print and related products, or a tightly integrated portal into your production systems that achieves efficiencies through automation, web-to-print has broadened its horizons and has something to offer printers of all types.