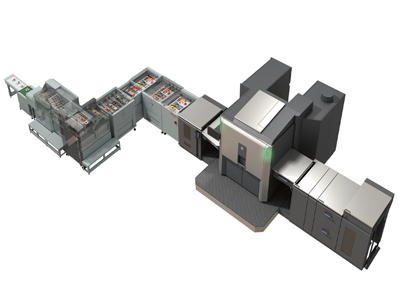

Horizon SmartStacker inline

Finishing for digital print is growing up with more robust products capable of handling higher volumes of work with full automation. Additionally, added value finishing is now more practical for smaller volumes and faster turnarounds.

A new generation of multi-purpose machines and modules such as Horizon’s SmartStacker and the Bourg Preparation Module (BPM) are providing industrial strength solutions to enable the production of finished products in a single pass without the need for any operator intervention. These follow on from an earlier generation of multi-finishers from Duplo, which has also continued to extend its range. Increasingly the option is for inline or nearline, as the use of JDF and barcode recognition enables the finishing machine to recognise each job and set itself up appropriately. The choice of which approach then becomes one of weighing up the benefit of increased flexibility of nearline versus the near instantaneous availability of completed products of inline.

As digital finishing gets faster and more robust a single machine may have capacity to handle the output of several presses, favouring a nearline approach. In the continuous feed/reelfed/digital web sector firms such as manroland web systems are bringing experience from web offset. The increased emphasis placed on offering a nearline system for digital, when an offset web invariably runs into a finishing line is a reflection of the need for increased flexibility.

At the same time as the physical processes are being separated, software, such as that firm’s MasterQ, utilise expertise in the end-to-end production process. This highlights the importance of automation not only to reduce manual handling but also the mental handling of production planning to maximise efficiency. As with the use of web-to-print and MIS to automate job management at the front end, it is increasingly important when handling lots of individual jobs to automate brain work and hand work.

One part of the new intelligence is the ability to sift through a basket of jobs and to group them together to maximise efficiency. While a machine may be able to automatically reconfigure itself between jobs that comes with a time penalty. Batching like jobs minimises that enabling machines to operate nearer their mechanical speeds, reducing the need to invest in multiple lines, so improving ROI. The Achilles heel of digital print used to be the lack of viable processes to embellish and add value. However, as digital print has become a more integral part of the production process, there has been an increase in processes available.

Embellishment

Specialist foiling firm Kurz has developed Digital Metal and the DM-Liner, which will be on display alongside the HP Indigo 30000 and 12000 presses on the HP stand showing enhancement of packaging and commercial applications with metal foil, including gold, silver, iridescent and hologram effects. The firm has also become part of the HP SmartStream Solutions Partner Program

The Scodix E106 is a B1 enhancement press, capable of up to 4000 sheets/hour that delivers multiple print enhancements, including sense, spot, braille, digital embossing, variable data finishes and foil. Compact Foilers developed the foil system while Mabeg developed paper handling.

GMP will showcase its Sleeking process to create effects with digital print using a laminator, including foiling, spot UV and holographic and metallic finishes. Sleeking foils can be overprinted, layered and laminated. GMPs range includes the entry level Exceltopic, medium run Q-topic and industrial level Protopic. Drupa launches include the Q-topic 380 Auto & Q-topic 380 Duplex. The Exceltopic-380 is a new entry-level semi-automatic laminator that runs at 8m/min and handles prints up to A3.

Kurz DM-Liner

Vivid Laminating Technologies will show two additions to its Matrix range, alongside a new wide format foiling laminator. The new Auto-Feeder can be fitted to the Matrix Laminating Systems while a high-speed model runs at up to 20m a minute. The Easymount AirFoil is a new wide format machine with independent pneumatic rollers that allow it to foil and add spot UV-style effects to wide format prints.

A new process, called Nano-Metallography, will be unveiled by Landa for labels, folding cartons, commercial print, publishing and flexible packaging, which is claimed enables metallisation at less than half the cost of foil, with zero waste.

Hohner has developed a new saddle stitcher. The HSB 9.000 a more user-friendly, faster machine, offering more options and a 7-inch colour touchscreen. The introduction of horizontal feeders brings a totally new dimension of possibilities.

Kolbus will show an enhancement to the KM200 Bookjet that it launched at the show in 2012 that adds the ability to change the height and width on a book-by-book basis in addition to varying the page count – one of the more difficult parts of makeready according to Kolbus – who believes this will be one of the most interesting products at drupa. The ability to change formats on the fly is thanks to a new three-knife trimmer the HD-HD143.

Morgana DigiFold high capacity

Morgana will introduce a high-capacity vacuum top-feeder that can take a sheet pile of up to 450mm, which features in the new versions of the DigiFold Pro and AutoCreaser Pro. The AutoCreaser Pro 385, with dual creasing blade and matrix, can run at up to 8500 sheets per hour.

The new Bourg Preparation Module (BPM) is a modular, scalable sheet preparation unit for Bourg binders and booklet makers eliminates operator intervention. It can work in-line, off-line, or in dual-mode connected to a Bourg Sheet Feeder (BSF), to create perfect bound or stitched books and booklets. The BPM eliminates or reduces time-consuming processes, such as preparing media in multiple sizes, manually setting up machines, and trimming finished jobs, minimizing the risk of error. The BPM is modular, each module can have up to four of the following functions: registration, rotation, creasing, and format changing.

CP Bourg BPM

Pulse is a new entry-level inserter from Pitney Bowes. ‘It will offer the full integration and track & trace functions of the firms higher end inserters but in a smaller and less expensive package. Drupa will also be the first time the latest version of the firm’s Epic inserter is exhibited.

Cutting

SEI Laser will show the laser powered PaperOne digital finishing and converting tool on its’ and HP’s stands. Developed in cooperation with HP it die-cuts, micro-perforates, pierces, engraves and marks to handle complex finishing of packaging, greeting cards, books, leaflets, posters, and envelopes at up to 2500 B2 sheets per hour. It has an automatic pallet loading and unloading system and handles paper, corrugated board and adhesive-coated stocks as well as PP, BOPP and PET in thicknesses from 150 to 600 microns.

SEI Laser PaperOne

Horizon is getting behind the Print 4.0 trend for Drupa 2016 and will show complete integrated solutions using JDF that improve the equipment efficiency across the 24 systems on show. There are six live presentations daily covering how to reduce waste, and minimize touch points featuring four systems. One of those will include the Horizon SmartStacker which intelligently cuts and stacks from a B2 printed sheet either online or offline. Another is the Smart Binding System for short run or book of one production. A new book block feeding device on the Smart Binding System enables feeding cut sheets from the SmartStacker into the binding. A new folding technology enables changing the fold pattern on the fly to minimize blank pages.

Highcon will expand its portfolio from one machine to three. To enable finishing work from the new B1 digital presses is the Beam, which can finish at 5000 sph. The Pulse is a 2000 sph B2 machine. Version three of the Euclid opens up new applications including full variable data cutting and 3D modelling using paper an additional application rather than a core market.

Bograma is launching a pared down version of its rotary die finisher. The BSR 550 basic offers short set-up times, simple operation and cost-efficient production. The off-line system is suitable for die-cutting, kiss-cutting, creasing, perforating and embossing.

Duplo will launch the PFi Di-CUT 300 rotary diecutter with an industry-first X&Y automated registration system using smart mark technology to counter image drift. It is operated by touchscreen panel that provides micro adjustments. It performs multiple cuts, slits, slit score, kiss cuts, perforations and window punches for single or multiple-up pieces, on a wide range of paper stocks at 3000 sheets per hour.

Manroland MasterQ

Roll to roll and end to end

As digital print has become industrialised and high volume, especially in continuous feed production environments such as books and digital newspapers, the need for industrial grade finishing systems has increased. Manroland web has leveraged its heritage in high volume web offset production to bring efficiency and control to the inkjet space.

Having developed the FoldLine fully automatic multivariable pin-type folder and FormerLine reel to book block line it has turned its attention to overall production efficiency, developing workflow software that takes pre press data and batches and imposes jobs to ensure maximum productivity by minimising downtime and changeovers.

The software that manages that is production planner MasterQ. This can be integrated with the MIS to drive the entire production process and to the individual printing and finishing lines by the means of a workflow bridge. It is also possible to integrate offset production from within MasterQ.

Users can define the way jobs are grouped according to a number of parameters. Sorting can be carried out automatically or using drag and drop. The software supplies print data appropriately to the press and can configure the FoldLine and FormerLine via JDF. It can also carry out a pre-flight report of the print and finishing of the job to check that production is possible based on the available equipment.

At drupa the equipment can be seen on HP’s and Kodak’s stands.